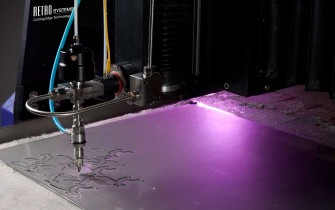

The water supplied to the intensifier is critical to waterjet cutting industries due to its direct influence on the service life of the equipment components such as check valves, seals and orifices. A high concentration of Total Dissolved Solids (TDS) causes accelerated wear of any components that come in contact with the high pressure water because of the increased abrasiveness of the water from the TDS.

Inlet water should be treated for either the removal of hardness of the reduction of TDS. Water softening is an ion exchange process that removes scale forming minerals such as calcium. TDS reduction can be accomplished with either deionization (DI) or reverse osmosis equipment. Generally, DI or RO provides better component life than water softening.

Products

- Multi Grade Sand Filter, Activated Carbon Filter and Iron Removal Filters

- Demineralization Systems (D. M. Plant)

- Reverse Osmosis System (R. O. Plant)

- Housing Filters and Cartridges